2025/03/19

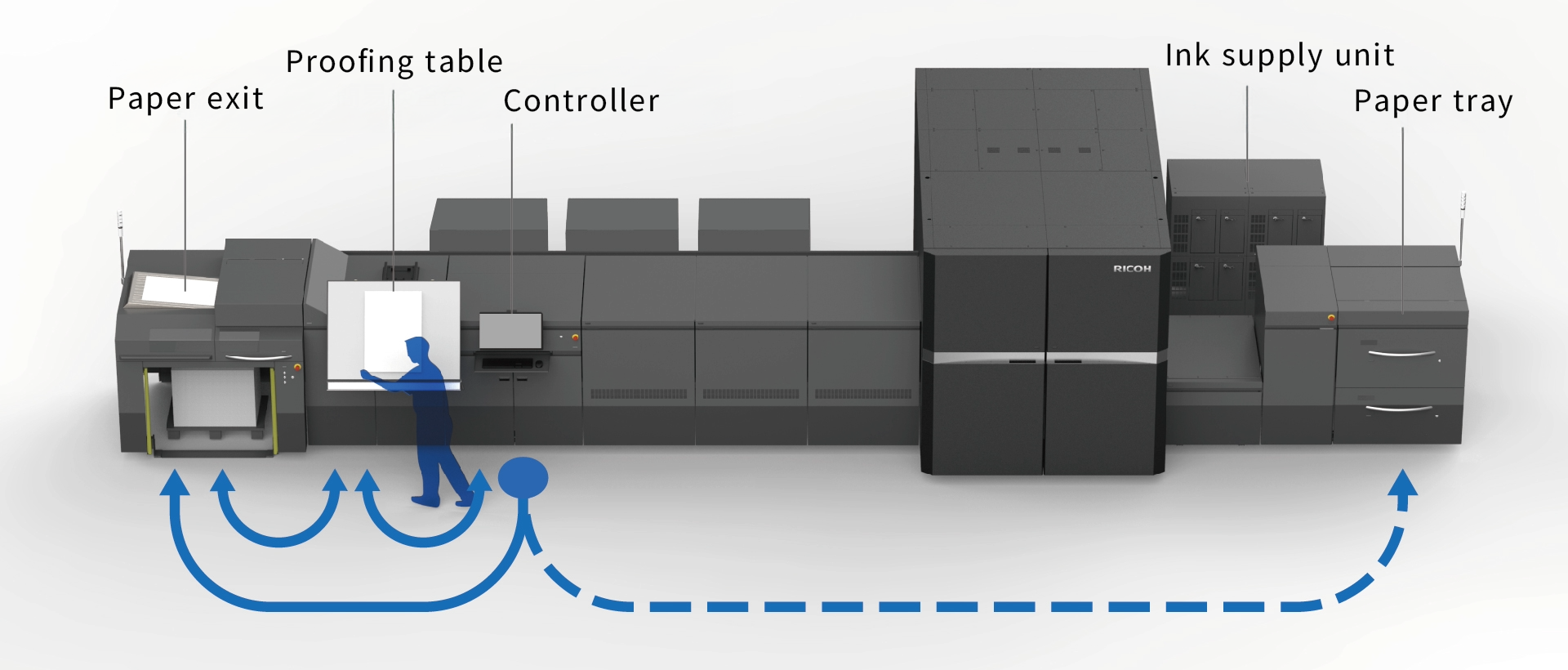

RICOH Pro Z75 is a B2 sheet-fed inkjet press. A sheet-fed press prints on individual sheets of paper. Launched in 2023, Pro Z75 is Ricoh’s largest sheet-fed digital press. Like the Ricoh Pro VC series of web-fed inkjet presses that print on continuous rolls of paper, Pro Z75 is also used in production printing. Compared to the printers that we use at home or in the office, these are very big machines. The configuration including options can be as long as 12 meters. The engine unit as the tallest unit is over 2 meters in height. Pro Z75 was developed to answer the professional needs of the printing industry. Here, we take you behind the scenes to show you how we designed it.

At the start of development, we used a 1/10 scale concept model to share with members how the product will look like. In particular, we paid attention to usability when maintaining the machine. For a printing press of this size, a lot of the maintenance has to be done by the user in order to keep the machine running. Because some of the maintenance areas are too high to reach, we needed to provide the user with something to stand on. We have never designed anything like that before. So, we tried to make clear the issues as early as possible. This enabled us to come to an understanding with the engineering department.

Next, we suggest how the operability should be, and apply it to actual methods and dimensions. The operator of Pro Z75 replenishes paper and ink, makes adjustments, and checks that jobs are printed correctly. Assuming that all the steps are performed by one person, they start by filling the paper tray at the right end, and then work all the way to the left end where they pick up the finished prints. Unfortunately, there is no way that we can reduce the size of the machine and make it a shorter walk. So, we tried to position the work stations based on our observations on how the operator actually works. One of these was the operation panel. With conventional presses, which are smaller, the operation panel is usually in the center. But for Pro Z75, we placed it near the paper exit. This allows the operator to check the prints and make adjustments without moving much. We also proposed an proofing table on which B2 size prints could be spread out for review. A table was not in the original plan, but the engineering department was happy to accept our proposal.

When the prototype is ready, our next step is to test it and improve operability. If a printer or copy machine in the office breaks down, you usually wait for a customer engineer to arrive. But Pro Z75 is factory equipment. If it breaks down, production stops. Therefore, the machine is designed for the customer to carry out maintenance by themselves so that it can be restored with as little disruption as possible. Some of the maintenance work require the customer to put their hands into the machine, or even get into the machine themselves. For the customer to work safely and quickly, we designers need to ensure that handles are easy to hold, buttons are easy to operate, and safety notations are easy to understand. So, we test again and again to find areas that need improvement.

The front of the machine was specially wrapped for the exhibition. As you can see, machine exterior can be covered with original graphics customized for the customer.

After going through this design process, Pro Z75 was finally launched in 2023. In June 2024, it was exhibited at drupa 2024. drupa happens once every four years and is the world's largest exhibition of printing technologies. It is held in Dusseldorf, where the movable-type printing press, said to be the basis for the modern printing press, was invented. At the exhibition, you can see all kinds of printing systems, big and small, by manufacturers from many countries. At Ricoh’s booth, together with other products and services, Pro Z75 was unveiled to visitors from all over the world. Our designers were also there to talk to visitors, and their feedback provided hints for further improvement.

For a big machine, many parts have to be designed. Development can also span a long period of time, so many designers were involved in designing it. The innovative design of Pro Z75 was highly praised, both in Japan and overseas. In Japan, it won a Good Design award in 2022; overseas, it was awarded an iF award in 2023.